- Unit 6, 5Th Fl., No.165, Section 5, Ming Shen East Road, Taipei 105065, Taiwan, R.O.C

- Tel : 886-2-27466046

- Fax : 886-2-27466048

- stimex@stimex.com.tw

- https://www.facebook.com/stimex.com.tw

Pilkington Plateau™

![]()

High quality glass for acrylic casting ![]() and industrial applications.

and industrial applications.

Chris Hill /Lucite International.

Pilkington Plateau™

Pilkington Architectural has supplied glass to the acrylic industry for over 60 years. Pilkington Plateau™products are made from specially toleranced Pilkington Plateau™glass to achieve the higher quality surface and thickness standards demanded by the acrylic casting industry and for other uses.

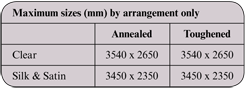

It can be purchased in a range of different finishes to provide a variety of cast acrylic sheet surface finishes. The standard thicknesses for Pilkington Plateau™are 8mm, 10mm and 12mm in both annealed and toughened form. Other thicknesses can be made on request.

"Pilkington is a world leader in the manufacture and processing of glass products. They have been supplying tempered glass to cast acrylic industry for over 60 years. Stimex is their exclusive agent in Taiwan, China, Philippine, Indonesia, Thailand, Vietnam and is also one of their major agents in Malaysia & Korea."

Benefits

- Pilkington has been supplying high quality glass to the acrylic casting market for 60 years.

- High quality base float glass – special tolerance float glass manufactured especially for Pilkington Architectural. This gives a special flatness to the glass which makes this ideal for acrylic casting.

- Thickness tolerance of the glass is maintained at a high level along with the wedge of the glass to provide a high tolerance glass mould.

- High strength glass (toughened) ensures improved safety during use and also improved longevity of the mould.

- Specially deigned manufacturing system to ensure the best quality during production.

- Quality control of each sheet of glass for the mould and specially inspected for the surface defects and also plate shape.

- Automatic shape measuring machine allowing for the pairing of similar glasses to ensure high quality and tolerance acrylic sheets manufactured.

- Pairing data supplied as well as plate data should the need arise to re-pair damaged glasses.

- Made by experienced personnel on a specially designed manufacturing and measuring line in order to supply high quality glass moulds for the cast acrylic market.

- Glasses are clear, toughened and annealed, supplied from a high surface quality, high tolerance glass.

- Pilkington Plateau™ can be made with a Satin or Silk etched surface offering alternative surface finishes. 6mm patterned glasses are also available as alternatives (subject to availability).

- Edge finish has been developed as a C profile in order to ensure longevity of the glass during manufacture and reduce damage to the glass edges.

- All glasses are packed in the export cases with paper interleaving and wrapped in plastic to protect the valuable casting surfaces.

BoBo Design /Lucite International.

Quality guaranteed

All glass produced is repeatedly inspected at both the glass manufacturing plant and at

our factory in order to produce a high quality

product with the following characteristics:

Surface Quality

Having invested in state of the art technology, you can be assured that both our annealed and toughened Pilkington Plateau™glass products are precision processed and inspected repeatedly. This ensures the required high quality finish with minimal surface defects, is maintained for precision acrylic casting. This new technology allows the deviation paired value (DPV) to be reduced to 0.6mm – 0.4mm, for an even more precise acrylic cast sheet.

LETO Kunststoff-Technik /Lucite International.

Edge Finish

Pilkington Plateau™is offered with a ‘C’ profile edge thus reducing the risk of breakage due to mechanical damage during the casting process.

Glass Types

Pilkington Plateau™is available in both clear and acid-etched finishes, giving the acrylic caster the option of either a gloss or matt surface. Three acid finishes, Opal, Silk and Satin, are currently available. Please enquire if you require a different finish.

Thickness Tolerance

At the manufacturing stage, Pilkington Optifloat™is carefully monitored so that thickness deviations within a plate are minimised. This gives the

final Pilkington Plateau™glass the following tolerances.

10mm Pilkington Plateau™

Clear +/-0.13mm max variation.

12mm Pilkington Plateau™

Clear +/-0.30mm max variation.

Wedge

This is the maximum difference between any

two thickness measurement points taken around the edge of Pilkington Plateau™glass.

Not to exceed 0.13mm for 10mm

Pilkington Plateau™Clear.

Not to exceed 0.20mm for 12mm

Pilkington Plateau™Clear.

Teiko /Lucite International.

Adamsez /Lucite International.

Tong Marks

Toughened Pilkington Plateau™glass will exhibit these marks close to one edge. For 10mm and 12mm toughened Pilkington Plateau™Clear glass the local bow will not exceed 0.4mm in any

305mm length when measured 25mm in from the tong edge.

Flatness

Every effort is made during the manufacture of Pilkington Optifloat™glass and the subsequent tempering to ensure that Pilkington Plateau™has optimum flatness. The flatness of the toughened Pilkington Plateau™glass is measured when the glass is in the vertical position to ensure the true shape of the plate, uninfluenced

by gravity or support systems, is ascertained.

The maximum allowable bow for 8mm, 10mm and 12mm toughened Pilkington Plateau™glass is:

Pilkington Plateau™Clear – 1.5mm/m.

Pilkington Plateau™Silk/Satin/Opal – 3.0mm/m.

Zone Creations /Lucite International.

Dimensional Tolerance

Both annealed and toughened Pilkington Plateau™.

Length and width to be within +/-3mm of nominal size.

Diagonals: Difference not to exceed +/-5mm.

Max size 2200 x 3300

Pairing

Through the use of various measuring devices and with the help of a specially designed computer software package, Pilkington Architectural is able to offer various pairing options.

In-Case Pairing

Pilkington Plateau™glass can be supplied already paired into “cells”, alleviating the need for sorting within the acrylic factory. If required, this should be requested at time of enquiry.

Pairing Data

Computer generated data can be supplied to help you determine the best possible pairing options.